TOUGHENED GLASS

This is achieved by heating annealed glass to approx 620*c within a furnace at which point it begins to soften. this is then cooled rapidly when broken, Toughened glass fractures into small pieces ( called dice ). As these particles do not have sharp edges and dagger points of normal broken glass it is generally regarded as safety glass.

Toughened glass must be cut to a size and have any other processes (drilling polishing etc..) completed before toughening because attempts to "work" the glass after will cause it to shatter.

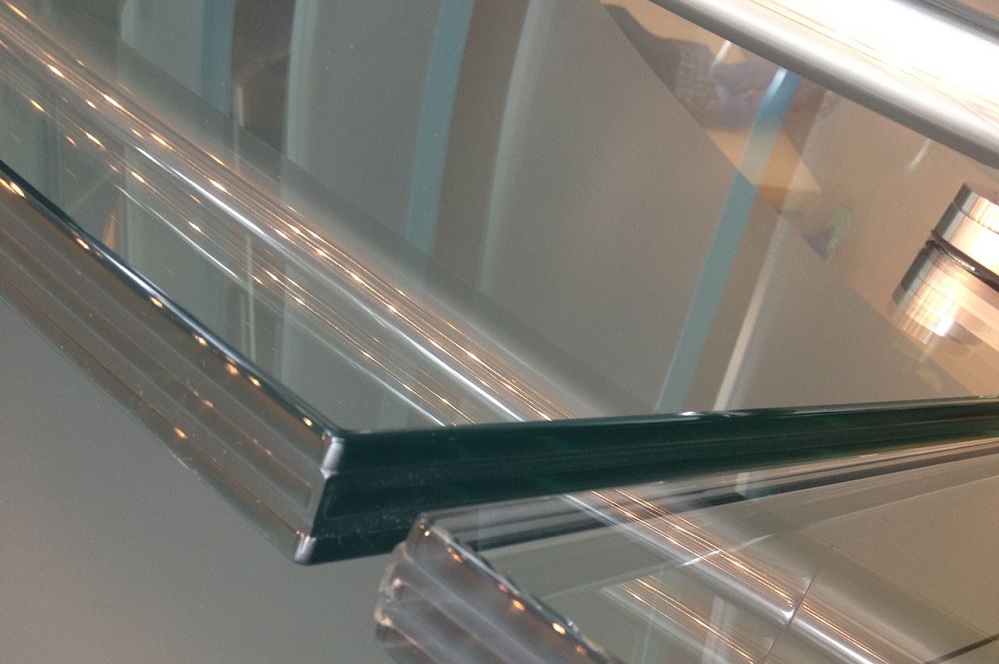

LAMINATED GLASS

Laminated glass is manufactured by assembling two panels of glass which are sandwiched together with PVB. This is, therefore a composite high performance product which combines the material properties of the glass with the unique properties of PVB such as adhesion to glass, elasticity and impact resistance.

When broken it will still remain integral due to the plastic between the glass, remaining safe even when broken. Although it breaks or cracks easier than toughened glass, it has a better security aspect as a much greater force is needed to break the plastic

MIRRORS

Mirrors are commonly made of glass with a smooth, polished surface that forms images by the reflection of rays and light, Mirrors are exceptionally useful and practical devices and are commonly used in every area of daily life.

The original method of making glass mirrors consists of depositing a coating of metal, mostly silver, on the surface of clear or body tinted glass. A layer of copper, which is in turn protected by a painted backing, usually protects this deposit. the silver gives its reflective properties